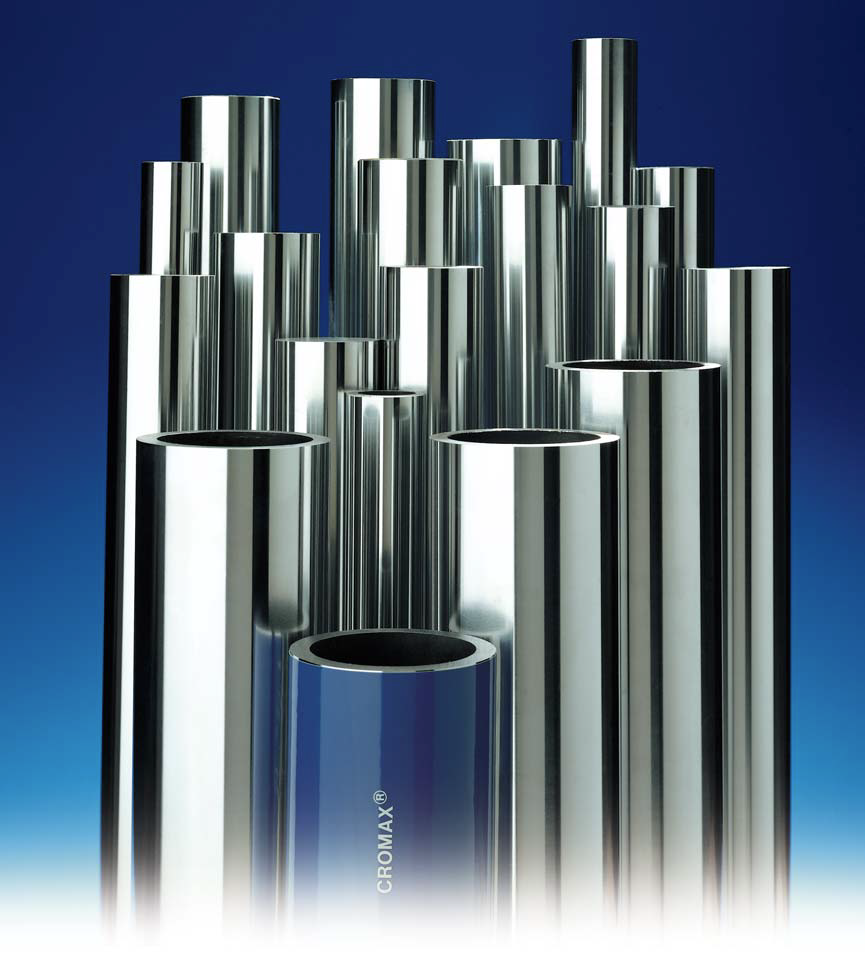

CROMAX TUBE – HARD CHROME-PLATED TUBE

- The thickness of the chrome layer is minimum 20 μm

- The surface roughness (Ra) is always less than 0.2 µm and normally in the range 0.05-0.15 µm. Rt (ISO) is always less than 2.0 µm and normally in the range 0.5-1.5 µm

- The chrome layer hardness is 850 HV0.1min

- The maximum deviation is 0.3 mm/1.0 m

- The out of roundness is maximized at 50% of the diameter tolerance interval

- ISO f8 is standard. Other tolerances can be supplied upon request (narrowest range is ISO level 7)

- Tensile strength (Rm): 550 – 800 MPa

- Yield strength (Re): 450 MPa

- Elongation (As): 20%

- Hardness (HBW): 160 – 240

- Resilience (-20°C): 27 J

- CROMAX TUBE

- EN 20MnV6

- DIN 20MnV6

- BS 55M

- AFNOR E420

- ASTM A572

INFORMATION:

The starting material for Cromax TUBE is either hot-finished or cold-drawn tube in a microalloyed, low-carbon weldable steel of 20MnV6-type. Cromax Tube exhibits a good combination of strength and toughness along with excellent machinability and weldability.

SPECIFICATIONS:

TYPICAL MECHANICAL PROPERTIES:

CORRESPONDING STANDARDS:

Below is the closest equivalent standard for the steel in Cromax TUBE.

Ovako Cromax is the major manufacturer in Europe of hard-chrome plated products in the form of bar and tube.

STANDARD SIZES (available in stock)

| OD x ID (mm) | Weight (kg/m) |

|---|---|

| 30 x 20 | 3.08 |

| 32 x 16 | 4.73 |

| 35 x 20 | 5.09 |

| 40 x 28 | 5.03 |

| 50 x 28 | 10.58 |

| 50 x 34 | 8.29 |